The heart of the power system is an 8 membrane P.E.M.(Proton Exchange Membrane) convection fuel cell. This type of cell is called a "stack", because it has multiple layers of membranes. This cell produces about 10 watts, and uses oxygen from the air, so no O2 tank is required. The cell has two hose barbs, one for hydrogen in and the other at the end of the stack.

At the time we got it, this fuel cell retailed for about US$1000. As mentioned elsewhere, we could not afford such an expensive cell, and it was only made possible by the generosity of Kate and the Fuel Cell Store. They allowed us to return a 3 watt cell we had bought earlier, and donated the balance of US$600!! Not only has the Fuel Cell Store been very generous, but they have been very helpful for technical information, ideas and resources. A huge thanks goes out to Kate and the Fuel Cell Store!!

One of the details of this type of cell is that during operation moisture builds up inside of the fuel cell. This moisture needs to be periodically removed from the fuel cell, or the output voltage drops drastically. In practice, this is accomplished by opening a valve attached to the hose barb on the end of the cell. A little hydrogen is flushed out, along with the accumulated moisture, and then the output voltage rapidly climbs back up.

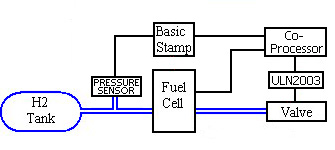

Block diagram of the power system

We have a water trap located between the fuel cell outlet an the valve, but it takes very long and hard run times to actually build up any significant moisture in the trap. However, without it, droplets of water can block the outlet hose, and the low pressure of the system isn't enough to allow the flushing process to happen.

Initially, we had the Stamp monitor the fuel cell voltage and open the valve as needed. However, it soon became obvious that it would be much better if a co-processor was used to accomplish this task and leave the Stamp free to deal with the robot. To that end, we designed and students built a co-processor module (CPM), and then performed the necessary brain surgery required to attach it to the main electronics.

The co-processor module is based on a PIC12F675, and programmed using PICBasic Pro. Code can be downloaded HERE. The 12F675 has an onboard 10 bit analog to digital converter, so it can run completely independent of the main system. Both the Stamp and the Pic can control the flush valve, with 220 ohm limiting resistors on the shared output. This way we retain the possibility of the Stamp using the valve when we want to do a manual or extended flush.

In operation, the CPM program checks the fuel cell voltage to see if it has fallen below a predetermined low point. If so, the valve is opened, and a tight loop is done until the voltage rises to a predetermined high point and then the valve is closed. The high and low points can be set via serial communication with the Stamp, and are saved in EEPROM during power down.

The flush valve is a normally closed solenoid type, made by Pneutronics. I had a lot of trouble finding a valve that would suit our needs of 5V activation, high coil impendence for low current consumption and mountable on a printed circuit board. I was just about to give up and settle for a less than ideal valve when we ran across Pneutronics. Not only did their very knowledgeable engineer help me figure out exactly what we needed, but Paticia was very helpful and got us three valves sent as samples free of charge! Thanks Pneutronics! These valves are really high quality, have a position-able input/output and have worked quite well for us.

The fuel tank is flexible pillow tank. We had been using Mylar helium balloons as tanks, but they were a pain to make, and popped after a number of uses. You can see our old style tanks HERE. We also suspect that the acetic acid evolved from the silicon sealant we were using may have damaged a fuel cell. We wanted to avoid a high pressure tank on the robot for safety and other considerations.

It took a lot of looking around to find a maker if pillow tanks who were willing to make such small, custom tanks. It was worth the search when we finally ran on to Peter Regena at Areo Tec Labratories. Not only were they willing to make the tanks, but they sent them to us for free! They also printed "CAUTION!! HYDROGEN" on the tanks, which is a good idea and looks cool too. Many thanks to Peter and Areo Tec Labratories!!

Initially we had a weighted platform to press the hydrogen out of the tanks. However, it turns out that the inherent elasticity of the tank material dispenses most of the H2 anyway. So the weight platform was removed. The system had originally been designed to accommodate both of our fuel tanks at the same time. In practice we found that one tank was enough, so the tower was cut down at the same time that we removed the weight platform.

During the school year of 2003/04, we experienced some erratic behavior in the power supply. Settings that worked for the flush system one moment didn't work well the next. As well, the fuel cell didn't seem to be putting out as much power as it did during initial bench tests. The system worked OK when the fuel call had a chance to warm up a bit, but cold start could be problematic.

Over the summer of 2004, I found the reasons for these problems. Firstly, the mounting bracket for the fuel cell was causing a slight short that was burning 300mA or more at all times. Grinding back the mounts solved that problem. Then I discovered that the co-processor was not retaining the fuel cell settings in EEPROM correctly. Further, I found another bug in the co-processor code that would allow the Hydrobot to think that fuel cell settings had been changed when in fact they had not. This combination of problems was causing the bizarre behavior. Since all of the assorted problems had been resolved, the power supply is quite reliable, and has no problems with cold starts.

An Important Note: As this is being written, the fuel cell has died and needs a complete rebuild. The cell died in much the same manner as another did one year earlier. We are investigating several possible reasons for this, as one has to assume that it is something we are doing. The difficulty lies in finding the problem, as very little practical data on using small fuel cells is available.

The main suspect is that in some configurations, power can be back fed into the fuel cell by the capacitors on board the robot after shutdown. That combined with the low level short mentioned above, which has been a long term condition, may account for damage to the fuel cells.

In order to eliminate this possibility, we are going to add a Shotkey diode to isolate the fuel cell from the rest of the system. While this means we have to accept a .7 volt drop, it is the easiest and safest way to make sure that the fuel cell never sees any voltage after shut down. In addition, we are going to implement a fuel cell monitoring program to be on the watch for slow incremental damage. Since the robot uses about 65% of the fuel cell's maximum output, we do not notice degradation in performance until substantial damage has been done.

So, once we get the rebuilt fuel cell back, we will perform a detailed series of load tests. Using these for a benchmark, we will take further measurements after every 5 hours of operation or so. We hope this will at least allow us to detect problems before we do serious damage to the cell. As we find the causes and solutions to this problem, we will be sure to update these pages!